Form Work Scaffoldings

Replacement of the many false and form-work systems which exist in today's market due to the wide variety of project types and shapes Falsework and form-work costs are minimized on every project which normally represents up to 40% 0f the total project budget. Using a 'DO IT ALL SYSTEM', such as the Multiform system, will result in an overall cost reduction of up to 30% on the cost of the false and form-work materials

A reduction in erection and dismantling time by as much as 50% which will result in huge savings on labour and a faster construction cycle Improvement in the finishing form and surface of the concreted member

OUR PRODUCT RANGE

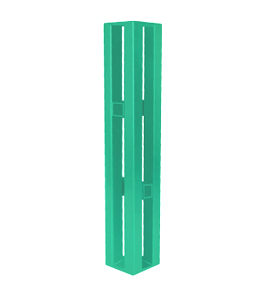

Code : RV2001

Well Soldier

R.V. Impex incorporate unlimited techniques to construct various structural elements. This system designed to cover wide ranges of construction and to withstand the high pressure exerted while pouring concrete members. The soldiers which are produced in many lengths can be assembled in combination to suit any heights of pouring. The system can be used for extensive applications, e.g. single or double soldiers shuttering system, inclined support, vertical shoring, horizontal support, supporting beam etc.

Code : RV2002

Corner Soldier

Designed to be used in congunction with standard soldiers, they simplify the construction of corners. By allowing ties to pass through in both direction, each corner soldier replace two standarsd soldiers. They permit the tie to be closer to the corner which in turn reduce the loading on external corner.

Code : RV2003

Corner Profile

It is used to support the shutter at the corner. Two corner profile of different shutter are tied together using tie bar & wing nut. The aluminium beams are fitted to the profile using universal clamp. The corner profile consist of a right angled bend sheet with holes at specified intervals.

Code : RV2004

Corner Stripping Piece

It is used to support the shutter from the inside face of the wall corner. It consist of an right angle bend sheet two square tube & required number of thread rod & wing nut. While assembling the plywood of the shutter is placed between the bend sheet & square tube.

Code : RV2005

Lifting Bracket

It is used to hold the hand rails of 48.3 scaffold tube. The hand rail post is fitted in to the socket of the access bracket and is fastened using M 16X 75 mm bolt and nut.

Code : RV2006

Steel Waler

It is a twin 100 � 50 mm channel section. Designed to make formwork elements using standard size plywood sheets. Simple, positive connections 110kN tie load capacity. Weight 22kg/m

Code : RV2007

Single Push Pull Props

It is used to support the shutter and is fitted at the back face of the steel soldier. It consist of an outer & inner pipe, sleev, two nuts, locking pin and base adaptor.

Code : RV2008

Double Push Pull Props

It is used to support the shutter and is fitted at the back face of the steel soldier. It consist of an outer & inner pipe, sleev, two nuts, locking pin and base adaptor.

Code : RV2009

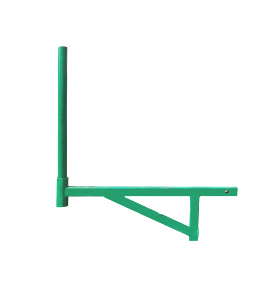

Access Bracket

Access bracket support three standard steel plank a toe board which provide a safe working platform. the bracket has a vertical pipe for fixing the hand rail post & a horizontal channel designed to carry timber or steel plank. the access bracket is fitted in to the hollow web of the soldier using one 16x75 mm bolt and nut.

Code : RV2010

It is used to hold the hand rails of 48.3 scaffold tube. The hand rail post is fitted in to the socket of the access bracket and is fastened using M 16X 75 mm bolt and nut.

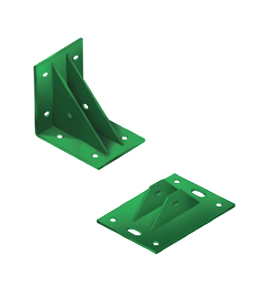

Code : RV2011 & RV2012

Push Pulll Corner Angle

Code : RV2013 & RV2014

Tie Plate